Streamline and optimize the remediation management of hydrocarbon contaminated sites with advanced technology.

The Challenge of Contaminated Sites

Regulators are mandating more aggressive investment, forecasting, and progress reporting. Portfolio managers need better data to understand complex site risks, prioritize projects and resources, and optimize remediation strategies all while striving to achieve more efficient closures at lower cost.

EMS Delivers Results

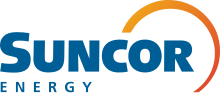

EMS’s Sensor and BioLodestone technologies make it easier to manage and close complex and remote hydrocarbon contaminated sites. Bioremediation treatments are tailored based on monitoring data from autonomous sensors. You gain effortless, detailed site models without the need for expensive manpower and on-site investigation time.

EMS Sensor Technology

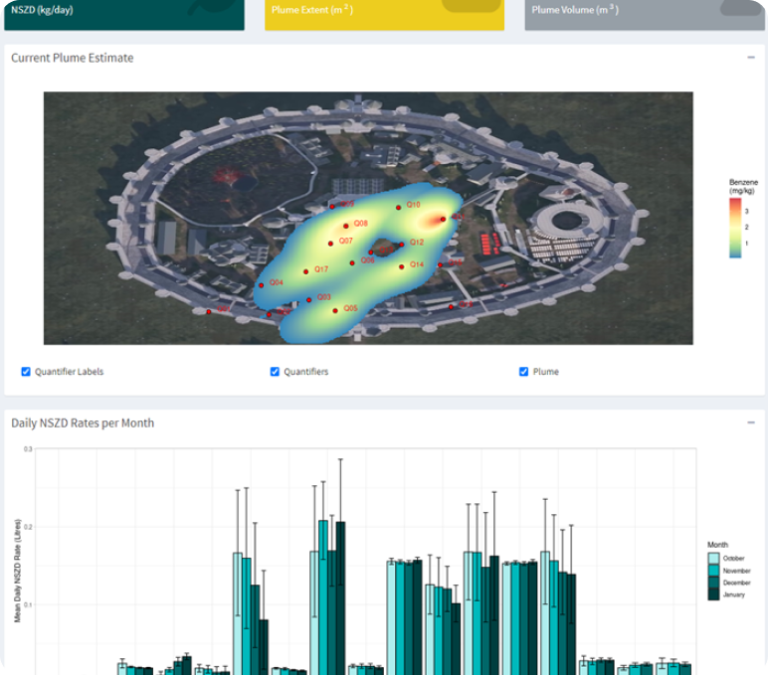

EMS’s SoilSense, WaterSense, and CropSense replace traditional sampling programs that only capture single point-in-time (PIT) data. Accurate, timely automated data collection results in a better understanding of contaminant plume profile and behavior, simplifying modeling soil and groundwater hydrocarbon degradation and seasonal impacts on risk and liability.

What EMS Sensors Measure

SoilSense

The SoilSense Difference

WaterSense

The WaterSense Difference

CropSense

Continually monitor soil dynamics to update yield predictions. Link input decisions to real-time yield potential, and understand nitrogen needs for next year’s crop.

The CropSense Difference

BioLodestone

Microbial Bioremediation

EMS injects tailored amounts of nitrogen, phosphorous, sulfur, and iron to boost microbial growth and ensure ample electron acceptors are available, which are critical for effectiveness.

Hydrocarbon Containment

Hydrocarbons from spills are primarily confined to a limited lateral spread due to strong adsorption onto soil particles.

Nutrient Optimization

The technology maintains soil pH within optimal ranges through buffer solutions, preventing adverse impacts from pH fluctuations on microbial activity and soil health.